Mastering In-Mold Decorations: Approaches, Trends, and Finest Practices for Optimal Outcomes

In the world of manufacturing, the art of in-mold decors stands as a critical facet of item design and manufacturing. As industries constantly look for innovative methods to improve aesthetic appeal and performance, mastering the ins and outs of in-mold decors has arised as an essential skill set. From picking the right materials to incorporating sophisticated design patterns, the trip in the direction of achieving ideal outcomes in this domain is multifaceted. By delving right into the approaches, trends, and ideal methods that underpin effective in-mold decor procedures, businesses can unlock a realm of possibilities that not only raise the aesthetic allure of their products however likewise enhance production effectiveness and boost customer involvement.

Material Option

Product option is an essential facet of understanding in-mold designs, as it directly impacts the quality and durability of the last item. When selecting materials for in-mold decorations, it is important to take into consideration variables such as compatibility with the molding procedure, the preferred aesthetic end result, and the ecological conditions the item will certainly deal with. Thermoplastic products like abs, polycarbonate, and polypropylene are generally made use of for in-mold designs due to their convenience and capability to achieve complex styles. These products use excellent moldability, making it possible for producers to create complicated shapes and patterns with accuracy.

Furthermore, the picked material must have excellent bond properties to ensure that the decoration sticks strongly to the substrate throughout the molding procedure. Adhesion between the product and the decor is critical for avoiding delamination and making sure durable visual charm. Furthermore, products with high warmth resistance are preferred for in-mold designs, particularly for items that will certainly be exposed to elevated temperatures during their lifecycle. By very carefully picking the ideal material for in-mold decorations, producers can improve the general high quality and longevity of their items, fulfilling the expectations of both end-users and clients.

Layout Technology

A necessary consider progressing the field of in-mold decorations is the continual expedition and application of style development methods. Style development plays an essential duty in boosting the aesthetic appeal, capability, and overall quality of items produced using in-mold decoration procedures. By integrating innovative layout aspects, manufacturers can separate their products in the market, bring in consumers, and remain ahead of competitors.

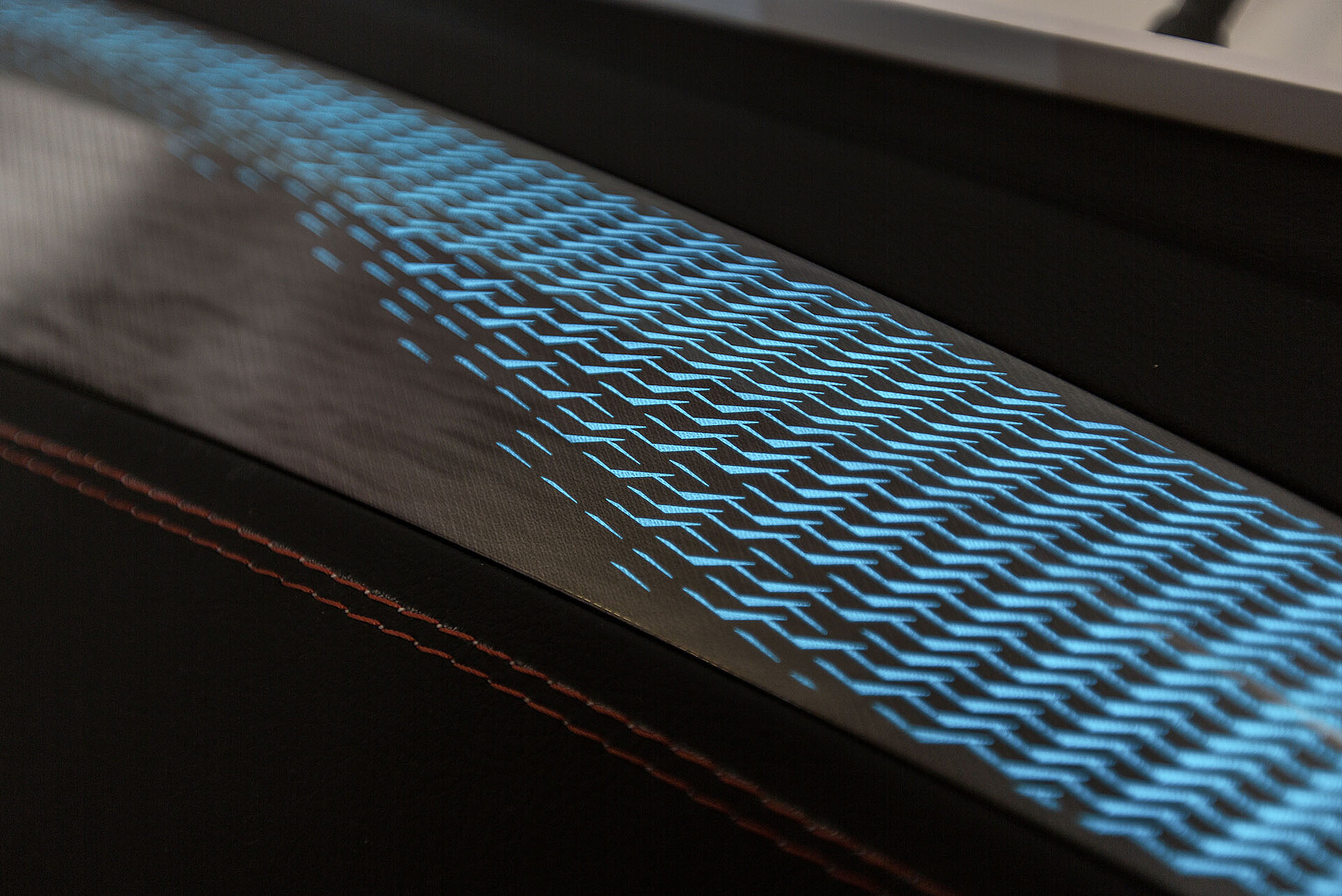

Among the key facets of style advancement in in-mold designs is the assimilation of elaborate patterns, appearances, and graphics that were formerly testing to accomplish with conventional decoration approaches. Advanced innovations such as 3D printing and electronic style devices allow developers to create facility and comprehensive layouts that can be perfectly moved onto molded components. In addition, making use of vivid colors, metal finishes, and special results like gloss or matte textures can additionally elevate the visual allure of in-mold decorated products.

In addition, design advancement expands beyond visual read the article appeals to incorporate practical improvements such as ergonomic forms, integrated functions, and personalized elements that satisfy certain customer needs. By accepting style technology, manufacturers can unlock new opportunities for personalization, product, and imagination distinction in the affordable landscape of in-mold decors.

Manufacturing Efficiency

Efficient production processes are important for equating the ingenious styles established in the field of in-mold designs into top notch completed items that satisfy market demands and read this article customer assumptions. In the world of in-mold designs, manufacturing effectiveness includes different essential aspects that contribute to the overall success of the production procedure. One critical component is the optimization of mold and mildew style and tooling to guarantee accurate and smooth decoration transfer onto the last item. By fine-tuning mold and mildew configurations and investing in premium tooling products, manufacturers can improve effectiveness and uniformity in manufacturing.

Automation not only speeds up the manufacturing procedure yet additionally boosts accuracy and repeatability, leading to an extra top quality and uniform end product. In general, an alternative technique to manufacturing effectiveness is vital in optimizing the possibility of in-mold design methods and achieving ideal results in the competitive market landscape.

Quality Assurance Steps

What are the key approaches for guaranteeing stringent high quality control measures in the world of in-mold decorations? Quality control procedures are paramount in in-mold decor processes to make sure the production of top notch and flawless completed items.

Utilizing sophisticated technologies such as automatic examination systems can also improve the quality control process by check here supplying accurate and reputable data for evaluation. These systems can detect flaws that might be missed out on by manual evaluations, therefore improving overall product high quality and uniformity.

Normal training and advancement programs for workers included in the in-mold decoration procedure can likewise add to maintaining premium standards. By informing staff on ideal practices, quality expectations, and the significance of focus to detail, firms can promote a culture of top quality awareness throughout the organization.

Consumer Allure

To improve the marketability of in-mold design products, providing and comprehending to consumer preferences play a vital duty in determining their charm and success. Consumer charm in in-mold decors is affected by different factors, consisting of layout looks, shade selections, longevity, and general capability. Consumers are increasingly seeking individualized and distinct products that reflect their individuality and design. Offering customization options such as customized designs, color variations, and textural aspects can substantially boost the allure of in-mold design items.

Conclusion

In-mold decorations offer a functional and effective method to boost product aesthetics. By very carefully selecting materials, embracing cutting-edge styles, optimizing manufacturing procedures, executing quality control steps, and prioritizing customer appeal, producers can achieve optimum results. It is essential for business to consistently adapt and boost their strategies to stay affordable out there. In-Mold Decorations. Mastering in-mold decorations requires an all natural approach that takes into consideration all aspects of the production procedure to make certain success.

In the realm of manufacturing, the art of in-mold decors stands as a pivotal facet of product layout and production. Design development plays an essential duty in enhancing the aesthetic allure, functionality, and overall quality of products produced making use of in-mold decoration procedures.One of the crucial facets of style advancement in in-mold designs is the assimilation of intricate patterns, appearances, and graphics that were previously testing to attain with typical decoration techniques.Efficient manufacturing processes are crucial for equating the innovative designs developed in the field of in-mold decorations right into high-quality completed items that meet market demands and consumer expectations. Offering modification choices such as tailored designs, color variations, and textural aspects can dramatically improve the appeal of in-mold decor products.